Water quality is crucial for wastewater treatment facility operators to maintain—not only to meet compliance standards for their effluent, but also to keep their systems running smoothly. As experts in helping you monitor and improve this key metric at your customers’ facilities, we offer powerful solutions that grow your business. In this brief guide, learn about the variables that contribute to water quality and discover how you can harness the power of bioaugmentation to help your customers see improvements.

Defining Water Quality Variables

There are three major variables that indicate water quality in a wastewater treatment system: total suspended solids, or TSS; chemical oxygen demand, or COD; and biological oxygen demand, or BOD (Figure 1).

Figure 1: A visual depiction of the relationship between the three main water quality variables.

TSS is a measurement of the amount of solids present in wastewater. The makeup of TSS varies from system to system, but it typically includes both organic and inorganic material. Organic elements of TSS include biomass (the living and non-living cells present in the system) and particulates (organic material from the influent). Non-living biomass and particulates are the components of many common problem-causers in wastewater, such as FOG and sludge. TSS is also a contributor to the values collected when conducting BOD and COD tests. By improving settling and digestion of TSS, you can improve all three of these water quality metrics.

BOD and COD are closely related, as they both have to do with oxygen. The BOD of a system is the quantity, in mg/L, of oxygen consumed by microorganisms in that system over a period of five days. A system’s COD is also measured in mg/L, but it represents how much oxygen is needed to oxidize all components in the wastewater. Similar to TSS, COD and BOD levels vary depending on the system. However, as a general rule, COD will always be higher than BOD, and in systems with difficult-to-degrade material, the ratio of BOD can drop even lower because of the lack of readily available organic material to digest.

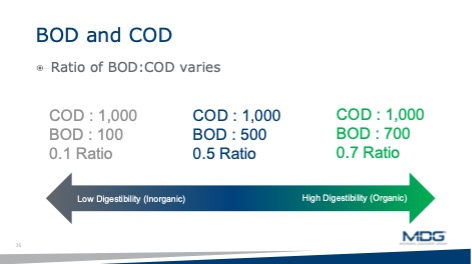

For example, a common ration of BOD to COD is 0.5. However, in wastewater from food facilities or municipalities that contains more organic material, this ratio can climb to 0.7 or higher. Conversely, in wastewater from facilities that deal with textiles, pulp and paper, or petroleum, the resulting BOD to COD ratio could be lower, around 0.1. This is due to the hard-to-degrade, inorganic material present in wastewater from these types of facilities (Figure 2).

Figure 2: A visual depiction of the variability of BOD:COD ratios.

How Bioaugmentation Can Help

If you want to offer an economical, effective solution to help your customers improve water quality in their facilities, bioaugmentation is the answer! MDG’s Biotifx® products contain high-performing strains of Bacillus bacteria that have been scientifically selected for their heightened ability to mitigate FOG, sludge, and other solids—all of which are components of TSS.

Additionally, our Bacillus increase the activity of the beneficial native microbial population in a system. They do this by producing a multitude of enzymes to encourage growth and by contributing to that activity themselves, digesting and removing organic material by breaking it down into more easily consumable forms. This process improves COD and BOD—as organic material becomes more readily available to the microbial population in the system, more of it can be digested faster, directly improving effluent quality (Figure 3).

Figure 3: Demonstrates the heightened ability of bioaugmentation organisms to increase biological activity and decrease the amount of organic material present in a system, as compared to the system’s native bacteria alone.

All of these improvements result in cost savings for your customers. For example, if a lagoon is struggling to digest sludge, facility staff may need to physically remove the sludge, process it, and haul it away in trucks, which is an expensive process. With bioaugmentation, however, sludge is converted into carbon dioxide by Bacillus and the beneficial native bacteria, leaving the lagoon through the air. This leads to less sludge buildup and a decreased need for—or even elimination of—physical sludge removal and the costs that come with it.

Put Our Solutions to Work

At MDG, Bacillus is our business, and your success is our success. If you’re ready to improve your customers’ water quality, boost your business, and reap the benefits of bioaugmentation treatment, connect with us today!

MDG is the Bacillus solution that helps you scale and streamline without sacrificing product effectiveness.