Keep Up to Date with MDG

MDG News and Updates

Your Custom Microbial Fermentation Roadmap

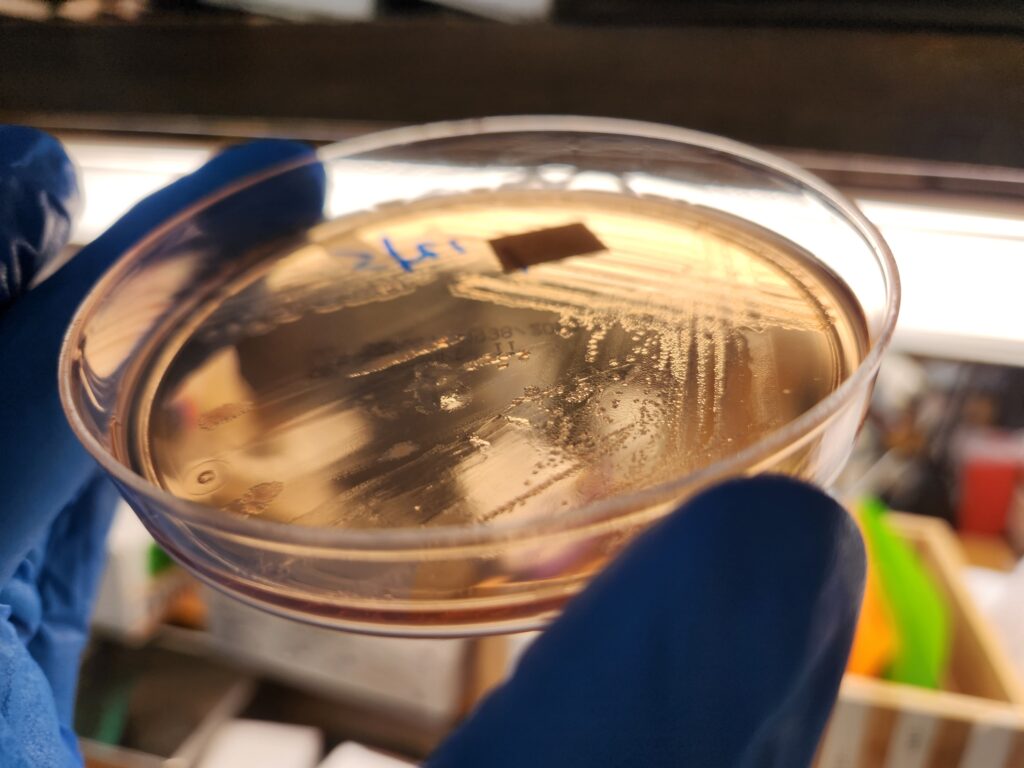

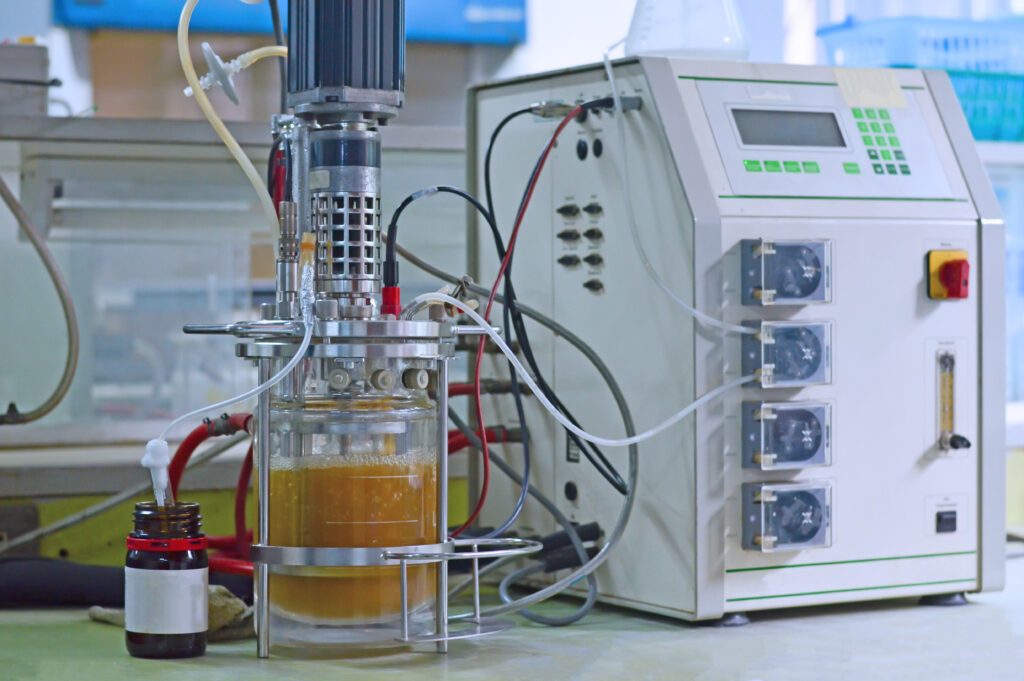

When you partner with MDG for your custom fermentation needs, you can be confident that our microbiologists and production experts are committed to delivering a final culture that fits your specifications. We follow our Trusted Process closely, fostering success for our customers. But what does that process look like? Read on to discover what our custom microbial fermentation process entails, from pilot scale to commercialization. Part One: Rapid Scale-Up When you begin the custom fermentation process with MDG, your Bacillus strain will go through a process development program. This stage typically takes about twelve weeks to complete. The process development steps are as follows: MDG receives your strain in our in-house labs. Our microbiologists streak your strain to ensure purity. An initial growth screen begins, during which our specialists test your Bacillus strain’s growth ability on a multitude of different media. Growth media is narrowed down to a few top choices, and additional testing is performed to find the optimal media for your strain. Once we’ve found the right growth media, we will grow your strain on a pilot scale, harvest and dry the culture, and send it to you for evaluation. After you give your approval […]

MDG: Your Key Partner for Probiotic Ingredients

At MDG, our foundation is Real Science. We have over twenty years of experience creating Bacillus-based solutions for our customers across various markets, and we stand behind the ingredients we produce. As the Human Health market grows, our emphasis on research and innovation makes us a trusted partner in probiotic ingredients for suppliers and manufacturers in the human health space. Read on to learn about our capabilities and discover how you can grow your business with our partnership. Strain Discovery and R&D Our microbiologists have generated libraries of over ten thousand isolated Bacillus strains that continue to grow as we innovate. Using various techniques that allow us to characterize strains both functionally and genomically, we conduct thorough screening to find strains with the best performance attributes for your probiotic product. With ongoing clinical trials, we’re keeping safety and ingredient effectiveness top of mind as we research, test, and validate. Manufacturing Processes MDG’s production facilities follow Good Manufacturing Practices and are FSMA-compliant and HACCP-certified for food and feed production. We emphasize strain purity and efficient, economic scale-up of your probiotic ingredients. Every aspect of our process ensures that the final product includes the intended strains in the specified ratios, resulting in […]

Increase Your Industrial and Institutional Cleaning Sales with MDG

Consumers in the industrial and institutional market are becoming increasingly interested in cleaning products that are easier on the environment. As a manufacturer, you may be looking to enhance your product offerings with microbial ingredients to meet this growing demand. If you’re new to biological solutions, we’re the perfect partner for you! We specialize in Bacillus, crafting high-quality bacterial ingredients that effectively reduce built-up waste, odor, and more across multiple applications in the industrial and institutional market. But our support doesn’t stop when we ship you the final ingredient. At MDG, we value long-term, strategic partnerships that provide support for your teams and help you take your business to new heights. Take a look at a specific example of how MDG’s guidance and support helped an industrial and institutional customer increase their sales of microbial-based products. Ingredient Support Part of our partnership includes access to the education and training you need to create an effective biological cleaning product. The customer received recommendations from our expert microbiologists on formulation best practices so that they could craft a high-quality product while reducing the chance of spoilage or decreased effectiveness. This guidance, along with additional market analysis, helped our customer make educated and […]

MDG Exhibits at the IWA World Water Congress & Exhibition 2024

Every year, we participate in trade shows and exhibitions around the globe, showcasing our innovative microbial solutions in the wastewater industry. This year, we will be attending the International Water Association (IWA) World Water Congress & Exhibition from August 11–15 in Toronto, Canada. This event offers MDG a platform to present our Bacillus strains, which are on the Canadian Domestic Substance List (DSL), highlighting the compliance and suitability for use in Canadian water management and environmental applications. About the IWA World Water Congress & Exhibition The IWA World Water Congress & Exhibition is a premier global event focused on water management and sustainability. The event gathers experts, decision-makers, and innovators to discuss solutions for water-related challenges. Our Role MDG partners with distributors and manufacturers in the wastewater treatment market to help them increase their sales and take their businesses to new heights with our unique Biotifx® platform. Focusing on bioaugmentation treatment, we offer our partners the education, tools, and hands-on support they need to succeed across applications. Find MDG at Booth #736—if you see us, stop by and say hi! While attending the event, we’re looking to connect with industry leaders, explore new collaborations, and promote our sustainable microbial solutions […]

How to Help Your Wastewater Customers Prepare for Winter

The changing of the seasons can have a pronounced effect on wastewater systems, particularly when the weather gets cold. Lower temperatures correspond to a decrease in microbial activity, which slows the treatment process. If you’re looking for a solution for your wastewater customers, we offer a product specifically designed to perform well in colder water temperatures: Biotifx® FRZ. How does Biotifx® FRZ work? The Bacillus strains in FRZ are scientifically selected for their ability to maintain their biological activity in colder water, specifically temperatures at or below 59°F/15°C. This means that treatment doesn’t slow down as much during winter, keeping wastewater facilities functioning more efficiently and avoiding system upsets caused by seasonal changes. In our in-house labs, we put our solution to the test against competing cold-weather biological products. Overall, Biotifx® FRZ performance stayed consistently high across both colder and warmer temperatures. Biological Activity Comparison As shown in Figure 1, FRZ maintained 92% of its biological activity during a drop in temperature from 77°F/25°C to 39°F/4°C. In comparison, the two competitor products we tested maintained only 1% and 5% of their biological activity throughout the same decrease in temperature. Figure 1: Comparing biological activity at 39°F/4°C to that […]

MDG’s Solutions to Portable Toilet Odors: A Guide for Distributors

As summer begins, outdoor events, construction projects, and gatherings become much more frequent, and portable toilets usually found at these locations can present a significant odor challenge. Managing those odors is essential for maintaining both public and environmental health. At MDG, we have extensive experience in microbial technologies, and our advanced biological solutions provide an innovative approach to tackling these odors effectively. Odors Have an Impact Odor control affects not only user comfort but also the overall acceptance and viability of portable toilets at public and commercial venues. When not properly addressed, the odors that portable toilets cause can cast the event—and potentially the portable sanitation suppliers—in a negative light. Effective odor management, on the other hand, can enhance customer satisfaction and bolster the reputation of distributors and event organizers alike. The Impact of Our Products Microbial solutions are a great way to combat odors, particularly in the application of portable sanitation. Unlike traditional chemical options, our biologically based treatments utilize Bacillus to digest waste materials, effectively reducing odors. A solution like this not only minimizes unpleasant smells but also contributes to a healthier environment by reducing the reliance on harsh chemical agents. MDG’s microbial products are also created with […]

A Guide to Wastewater Success: People, Products, and Programs

Working in the wastewater treatment industry comes with its challenges. Your customers may face problems like sludge buildup, odors, hydrogen sulfide (H2S) production, and fats, oils, and grease (FOG) accumulation. As their supplier, you need a solution you can count on to help them succeed. That’s where we come in with our innovative, research-based, and hands-on platform: Biotifx®. Our Biotifx® platform includes access to our wastewater treatment product line, expert-led training to drive application success in the field, and continual support from our team members throughout the sales process. We break these benefits into three main categories: People, Products, and Programs. Read on to learn more about each of these three pillars and how MDG’s Biotifx® platform can help you bring successful Bacillus-based solutions to your customers working in wastewater treatment. People When you partner with MDG, you can trust that we are dedicated to helping you achieve your goals in the marketplace. From training and field support to assistance with administrative tasks like product line development and private labeling, we walk with you on your wastewater bioaugmentation journey to show you just how successful you can be. We know how important it is to talk to real people to […]

The Commercialization of Microbial Solutions

As a Bacillus manufacturer, we work to grow our partners’ pure single-strain Bacillus cultures and scale the process so that they receive exactly what they need. Our success in the commercialization of microbial solutions comes from our trusted process and our commitment to quality and partnership, so that the transition from concept to commercial is not just a possibility, but a proven outcome. The Growth of Bacillus At the heart of our success is a deep understanding of microbials and their potential in multiple applications. The initial step in our process is optimizing the Bacillus culture for maximum growth. We measure a strain’s growth in a variety of media, ultimately landing on the one best suited for highest yield and setting the stage for success throughout the rest of the commercialization process. A Partnership for Progress At MDG, we put our partners first. When we grow your Bacillus culture, we work closely with you to refine and improve processes to ensure you’re receiving the strain and yield you’re aiming for. To make your journey to market successful, an active and involved partnership is key. We’ve seen this collaborative effort lead to efficiency and proven marketplace success for our customers. Custom […]

How to Handle Odors Within Septic Systems After Spring Thaw

Spring’s warmer weather and longer days are always welcome after a cold winter, but for septic tank owners and operators, this seasonal transition can bring a significant problem: odors. Now that spring thaw has occurred and the heat of summer is setting in, septic tanks can emit unpleasant odors, and your customers need to find a solution. MDG is here to be your partner in creating that solution, providing you with the education, tools, and hands-on support you need to formulate an effective, microbial-based product that combats septic tank odors due to spring thaw. Odors Created During Spring Thaw After spring thaw, septic tank owners and operators may notice new or more intense odors than normal. This is because: Bacteria resume activity When temperatures get colder in the winter, the bacteria that break down waste in the septic tank may become less active or dormant. When the system starts to warm, these native bacteria become active again and resume the process of breaking down waste, which can produce odors. Compacted snow and ice melt Melting snow and ice can soak into the ground around the septic tank and drain field, which might impede the system’s ability to properly drain and […]