With environmentally friendly cleaners continuing to trend, more and more chemical manufacturers want to know – what’s inside a bio-enzymatic cleaner?

In this article, we’ll walk through some of the common building blocks within formulations. Not all ingredients are essential for every product as it depends upon the application, but by understanding each element, you’ll know what you may want to request when discussing products with a manufacturing partner like us.

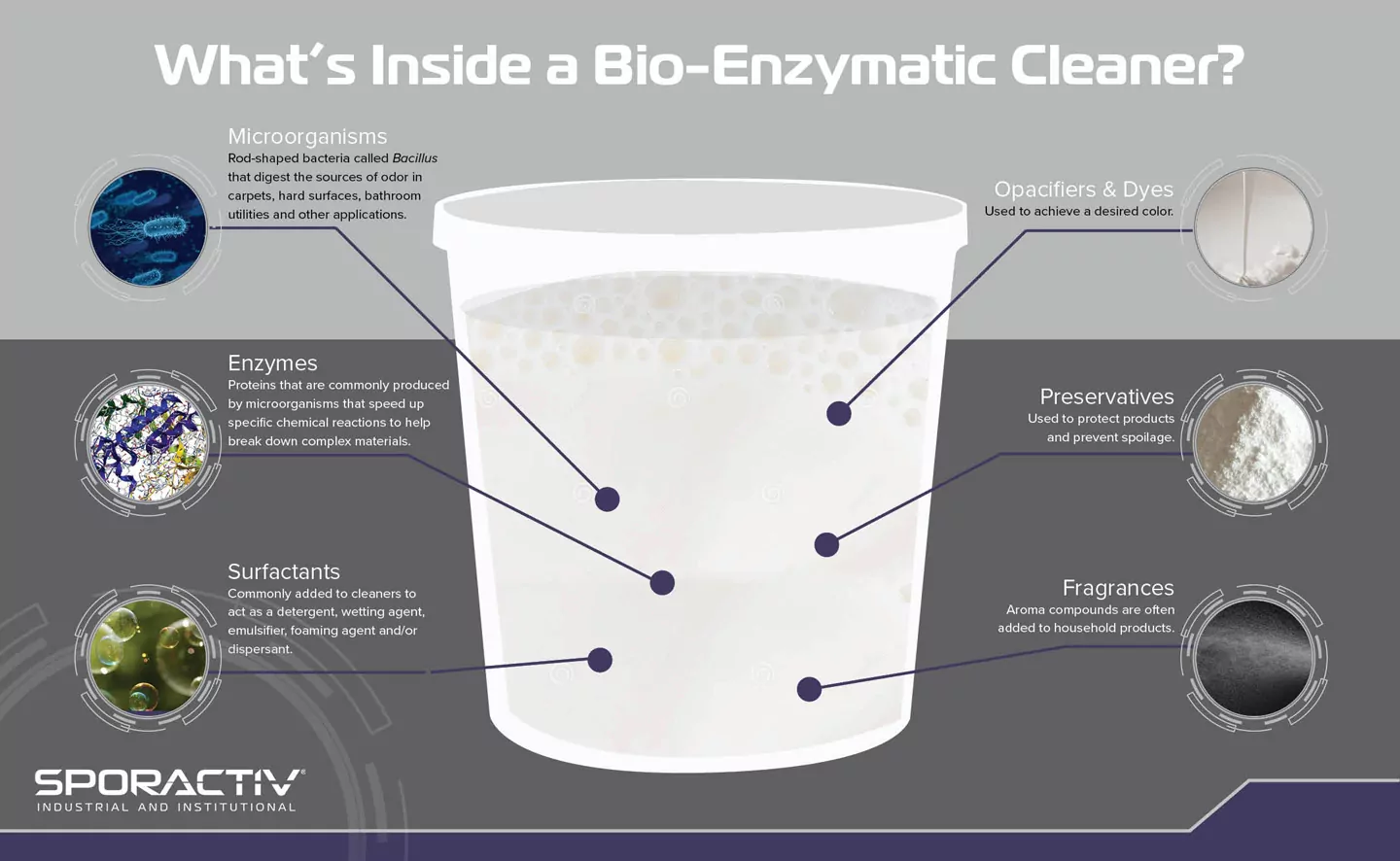

Microorganisms

A foundational ingredient to many bio-enzymatic cleaners are live microorganisms. At MDG, we manufacture a type of rod-shaped bacteria called Bacillus that can be used in janitorial and sanitation cleaning solutions to reduce fats, oils, grease (FOG) and the sources of odor in carpets, hard surfaces, bathroom utilities and other applications.

Enzymes

Enzymes are proteins that are commonly produced by microorganisms, including Bacillus, that speed up specific chemical reactions to help break down complex materials like fat, oil, grease and even paper products!

Adding enzymes to industrial and institutional bio-enzymatic products such as household cleaners and odor removers can accelerate the cleaning process and increase effectiveness. These enzymes act immediately, allowing microorganisms present to metabolize the nutrients efficiently.

Surfactants

Surfactants are commonly added to cleaners to act as a detergent, wetting agent, emulsifier, foaming agent and/or dispersant.

On a microscopic level, surfactants help lower the tension between two liquids, such as water and oil, and allow the Bacillus in bioaugmentation products to hydrolyze, oxidize and digest fats, oils and grease (FOG) more easily. Aesthetically, surfactants also create a foaming effect which is often preferred by consumers.

Surfactants are recommended for products that are used to treat FOG or require foaming (e.g., some cleaners and detergents). To avoid foaming during mixing or blending, you may choose to exclude surfactants from your formulation.

Opacifiers and Dyes

Another ingredient that can be added for aesthetic reasons is an opacifier or dye. Opacifiers increase a product’s opacity by making it more white in color which may be more visually pleasing in products containing enzymes or microbes that are naturally beige in color. Dyes can be used for similar purposes to achieve a desired color.

Deciding whether to include an opacifier or dye is optional and based upon your customer’s preference. Some applications do not require the product to look appealing, therefore costs can be saved by excluding.

Preservatives

Preservatives are used to protect products and prevent spoilage. We highly encourage all chemical manufacturers and distributors servicing the Industrial and Institutional industry to include preservatives in bioaugmentation liquid formulations as they prevent the growth of unwanted microorganisms and increase shelf-life.

Making sure products are diluted appropriately by referencing the number in front of the X on the product label can help prevent products from being under- or over-preserved.

Fragrances or Odor Counteractants

Like opacifiers, adding a fragrance is optional and based upon your customer’s preference. Aroma compounds are often added to household products such as those containing microbials (e.g., pet stain removers, cleaners and detergents) as homeowners prefer products that leave behind a pleasant smell. While the Bacillus work to remove the source of the odor, some fragrances can help mask the odor in the meantime. Odor counteractants may also be used which help to encapsulate or neutralize odors for immediate effect.

It’s important to note that it’s not necessary to add fragrance or odor counteractant to a product, especially in situations where it may be diluted.

MDG Has Your ‘Bac’ with Bacillus

In the world of cleaning, we’re passionate about helping our manufacturing partners contribute to a healthy environment. As a partner, we offer technical support and microbial formulation guidance. We’ll ensure you’re offering the right mix of microbial-based products to enhance your cleaning line. Contact us and a bio-enzymatic cleaning expert will be happy to discuss options with you.