When it comes to treating wastewater lagoons and ponds, our partners follow our full-service treatment approach that combines premier bioaugmentation products, step-by-step treatment programs, and in-field support.

This unique combination creates a complete solution that brings real success to their customers – just like this real lagoon treatment story!

BACKGROUND

One of our distribution partners (DPs) was working with a beverage manufacturer who was utilizing evaporative wastewater holding ponds. Once a pond was filled, they allowed it to dry completely before excavating solids and refilling. A typical cycle included one month to fill the pond, followed by three months of drying.

THE CHALLENGE: SLUDGE + ODOR

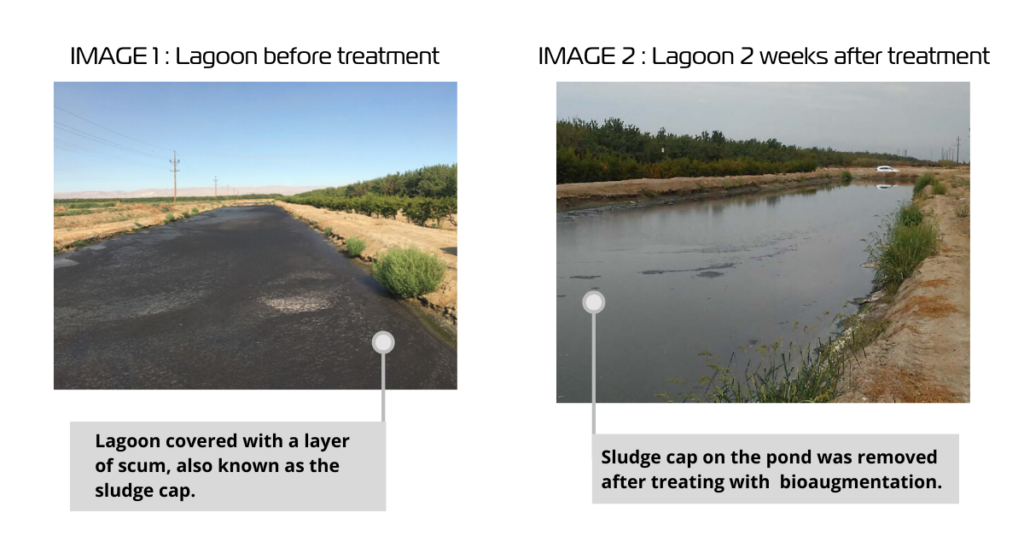

Over some time, an issue arose when a persistent sludge cap formed on the surface of the water. This cap started preventing water from evaporating within their normal three-month cycle and it caused the pond to become anaerobic, releasing strong, unpleasant odors.

THE SOLUTION: BIOTIFX® PRODUCTS + PROGRAMS

By working with our technical service team and following the step-by-step Lagoon Treatment Program, our DP was able to determine WHERE, WHEN, and HOW MUCH of Biotifx® ULTRA was needed for treatment. Data was collected before, during, and after and included pictures of the sludge cap, basic water chemistry monitoring, and an odor survey.

RESULTS

After two weeks of treatment, the sludge cap on the lagoon was decreased and odor reduction was much greatly reduced. Within the following week, the cap and odors had been completely eliminated.

TAKEAWAYS

- The Bacillus within Biotifx® ULTRA were able to make significant progress on digesting the sludge cap in just two weeks’ time.

- By following our Lagoon Treatment Program, our DP was able to win the business, formulate a complete treatment plan, and execute a successful treatment.

- The success our DP experienced created a longstanding loyal customer and lead to more lagoon opportunities.

Interested in getting more of the details from this success story? CLICK HERE to view this case study in its entirety.