Many of us know what happens when you mistakenly under-preserve a biological product: the bottles start to bulge or suck-in (the latter can also be caused by fragrance issues), fungal growth starts to appear or it starts to have an unpleasant odor. But do you know what signs to look for if your product is over-preserved?

There is usually one noticeable sign of an over-preserved product: the customers who were consistently using your product haven’t placed an order in a while.

Understanding Preservatives

The preservation system in your biological product is a double-edged sword. If you under-preserve, you get the problems mentioned above. But if you over-preserve, your product won’t work, or it will have a significant delayed reaction. This can lead some of your repeat customers to think that the product no longer works.

Over-preservation occurs when too high of a concentration of preservatives is present in a product. The preservatives are meant to be diluted to a predetermined point as indicated by the number in front of the X on the label (i.e. a 10X product would be 1 part product, 9 parts water). Diluting to the proper point allows the product to activate and begin working. If over-preserved, the product isn’t diluted enough to allow activation.

Effects on Application

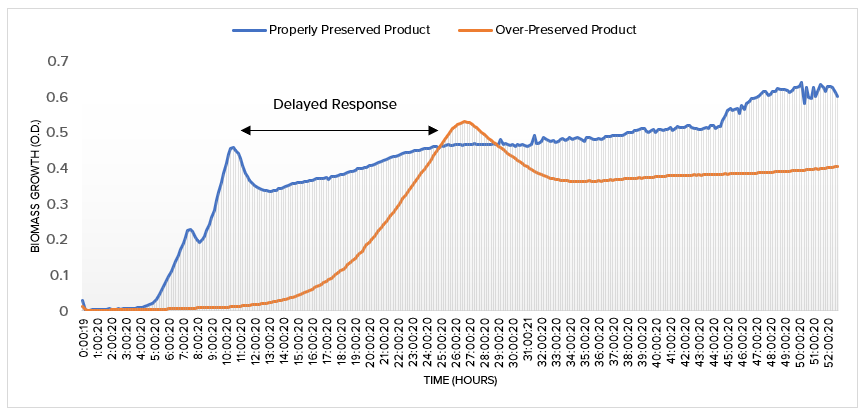

The below graph (Figure 1) shows an example of an over-preserved product. As you can see, the properly preserved product began to grow 16 hours sooner than the over-preserved product. Depending on the application and holding time, a delayed start like that of the over-preserved product can kill your treatment success. Grease traps, multi-story drain treatments and septic piping are a few examples of systems that have narrow activation windows where over-preservation can limit your repeat business.

At MDG, we’re dedicated to honoring the brand and reputation of our partners. Proven Success is our measure of a job well done and is our promise. As one of our partners, we’ll show you how to properly dilute products so that you can avoid getting over- or under- preserved products. If you suspect issues with your current supplier, reach out to us and we’ll see what we can do to help.

If you’d like to learn more about our products and support services, send us a message and one of our representatives will reach out to you.

Figure 1 – This graph illustrates how an over-preserved product can have a negative impact on product application. If over-preserved, the product may not work, or it will have a delayed reaction which can have a negative impact on treatment.