Interested in Custom Fermentation?

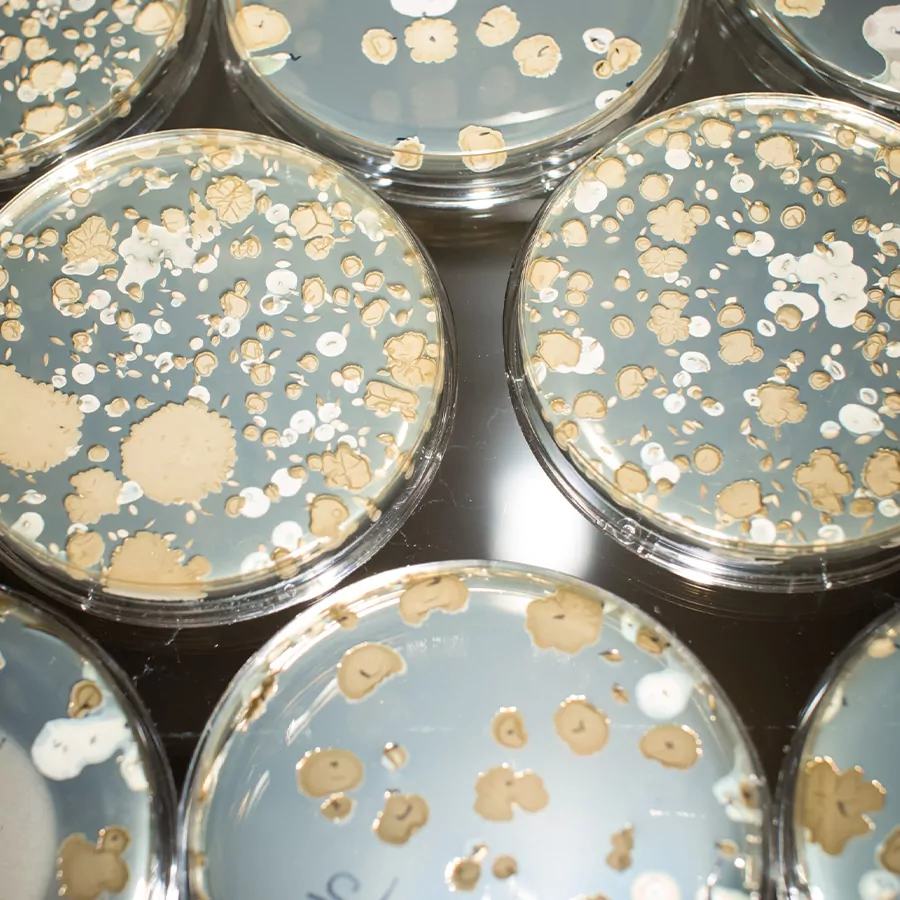

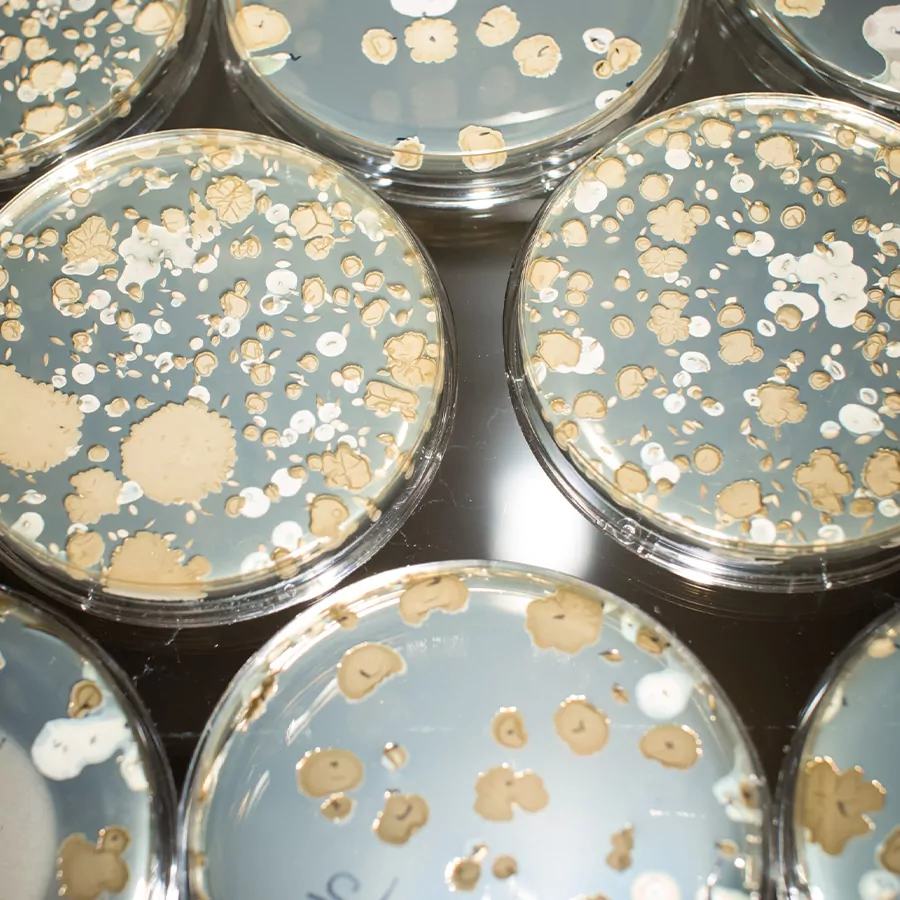

We grow Bacillus.

We are The Global Leader in Bacillus and when you work through the custom fermentation process with us, the quality of our craft shows through. Click the link below to view a Video tour of our process and facilities.

Learn More

Fermentation & Manufacturing Capabilities

Cutting edge equipment and optimized processes. MDG can accommodate both the large and small-scale fermentation needs of our customers with speed and consistency.

View Our Capabilities

Interested in Custom Fermentation?

Our expertise in custom fermentation affords you the confidence to expect high-quality, consistent Bacillus strain manufacturing delivered with efficiency and integrity.

Application Specific Programs

We grow Bacillus

We are The Global Leader in Bacillus and when you work through the custom fermentation process with us, the quality of our craft shows through. Click the link below to view a Video tour of our process and facilities.

Learn More

Fermentation & Manufacturing Capabilities

Fermentation &

Manufacturing Capabilities

Cutting edge equipment and optimized processes. MDG can accommodate both the large and small-scale fermentation needs of our customers with speed and consistency.

View Our Capabilities

What Sets Us Apart

Rapid Scale Up

Once you have found the perfect strain, the final step to commercialization is to scale your product. We have the team and facilities to allow you to scale rapidly, accurately, and economically. From pilot scale product to customer trials to manufacturing scale once you are ready to go to market, MDG has you covered.

Capacity

With 35,000 liters of large-scale fermentation capability and the downstream process to match, MDG can provide our clients with speedy turnaround times. Getting strains out the door in 90 days or less makes your final stage to manufacturing a seamless process.

Quality Programs and Certifications

MDG is FSMA-compliant and HACCP-certified for food and feed cultures and products. GMP is a core element of FSMA and HACCP. It covers everything from the cleanliness of the facility to the handling of ingredients and finished products. At MDG, GMP is implemented for all production processes, regardless of market. We also follow extensive quality control checkpoints to ensure purity from start to finish.

Blending and Packaging (In-House)

The need to outsource has become a thing of the past for MDG customers. Our fermentation capabilities are seamlessly complimented by our extensive in-house downstream processes. This saves our customers time and money by providing various blending and packaging capabilities.

MDG Employees

We firmly believe one of our biggest assets lies within our MDG team. MDG is proud to employ an experienced staff that truly cares about our customer’s and our vision to Feed, Clean, Save The World.

Real Science, Trusted Process, Proven Success

It’s our foundation and our promise. A strong scientific understanding of Bacillus and our optimized fermentation processes consistently yields measurable success for our customers.

Industry Reflections

Capabilities